Working with a DIY Inventory Management System?

We all love the idea of being self-sufficient – both in business, and in life. But when it comes something technical (like setting up an inventory management system for your business) the DIY approach isn’t always the best way forward.

We talk to hundreds of businesses every year which means we’ve seen just about every kind of implementation of a business system there is. From the top-notch projects that are carried out by trusted partners, to slapdash implementations completed by unapproved consultants. We’ve also seen our fair share of DIY self-implementors and we can tell you this:

If you’ve set up your own inventory management system, there’s a good chance you’re not getting the most out of it.

Taking the leap to invest in a brand-new inventory management software takes a lot of time – and a lot of money. So, if you’ve made this decision, you want to be sure that you’re getting the highest return. We talk to many clients who have done their own due diligence to research into a business solution that best solves their pain point, they’ve implemented the system but it’s still not working for them. And that’s where we come in – if you’re in this position, we can help you be confident your management system is properly set-up, make sure it’s fulfilling your needs, and get your operations running smoothly.

There is a way you can troubleshoot this yourself, which is by completing a thorough self-assessment. In this blog, we’re going to take you through the different areas to look at to ensure you’re getting more bang for your buck with your inventory management software.

Here are four of the most important questions you need to ask yourself…

1. Have your users been trained?

When you think about implementing an inventory system, it’s easy to become focused only on the software. But the best software in the world won’t help if your users don’t know how to use if effectively to get results.

At the very least, they should be confident with the most basic functions they need to use day-to-day. These are things like entering data, processing orders, and generating reports.

As a general rule, we’d recommend at least 3 hours of inventory system training for each user. We provide training for our clients as part of our service when implementing scalable software into their business. But even if we haven’t worked with you on your initial implementation, we can still provide training support to get your team up to speed.

2. Are you using all the data fields?

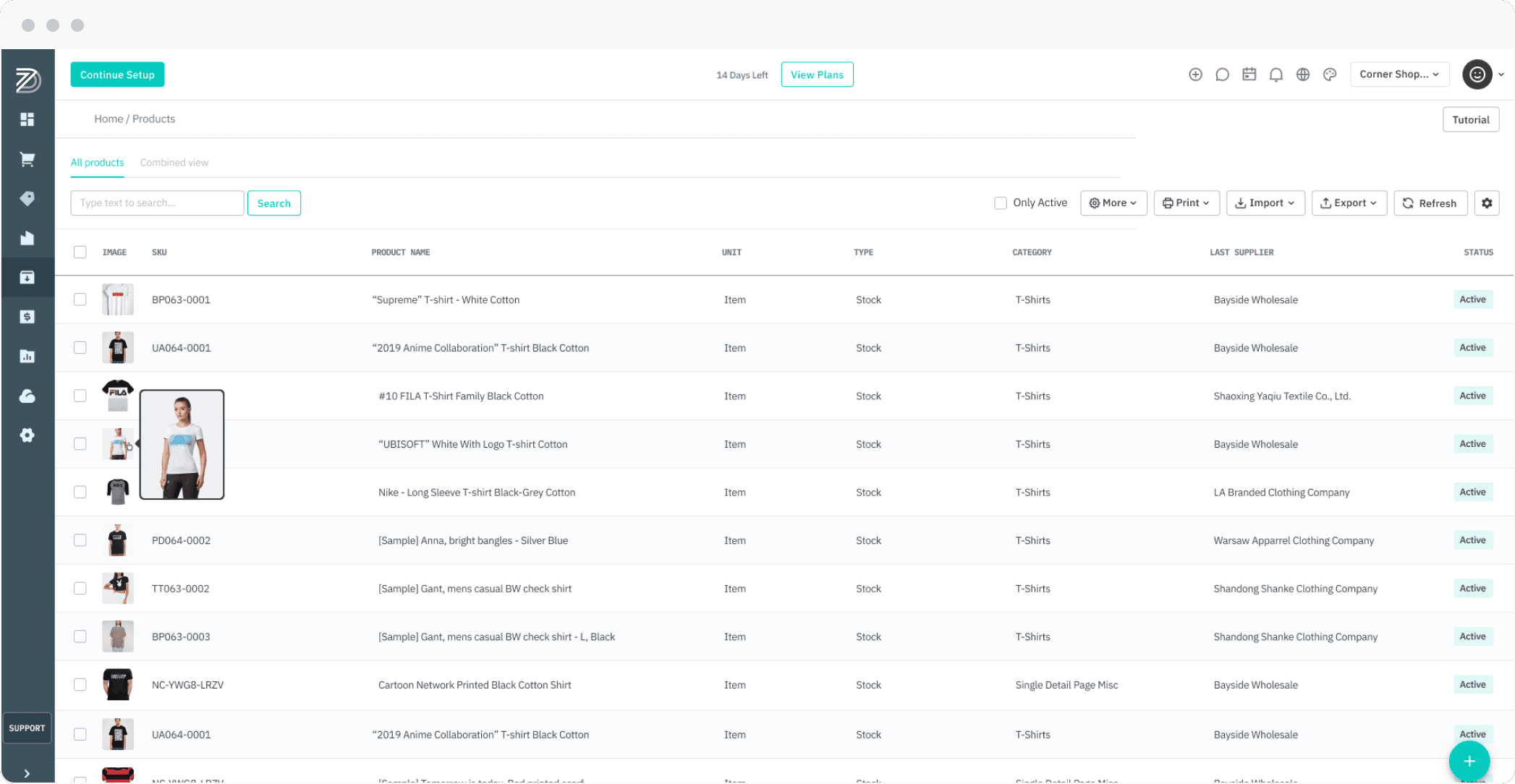

Most inventory management systems come with a huge range of different data fields for your products, customers, and suppliers. These aren’t just padding to make the software seem comprehensive; these little details are essential tools in improving your efficiency and the visibility of your data. This is just one simple area where you can see massive returns on your investment for just a small change in your habits.

When you start to fill out every available data field, you’ll open up a whole new world of functions and high-speed access. You’ll be able to filter your products by their category or supplier, compare customers across different locations, and generate in-depth reports based on every bit of data you’ve recorded along the way.

3. Have you set up all your integrations?

Some businesses think that once their inventory system is up and running, there’s nothing left to do. But if you’re already using a cloud accounting app, it’s almost guaranteed that your business is relying on several other separate bits of software too.

If you’re not letting your inventory system communicate with the rest of your software, you’re missing out. Put simply, system integrations are a way of linking the different parts of your business through the apps they use. This allows them to share data and ensure that all of your systems have the same, up-to-date information. If you’re looking to improve efficiency and reduce your errors (and you should be!), getting the right software integrations is a huge step forward.

When your sales team records a sale, your accounting software records one too. Your inventory system will adjust its stock levels, and your logistics provider will receive the update it needs. It all happens automatically, and there’s no need for double entry – which also means a massive reduction in the risk of human error.

4. Are your reports showing the correct values?

Modern inventory systems aren’t just about automation. They’re about business intelligence and data – getting fast and useful insight into the inner workings of your business and how it operates. And if you want to be able to trust those insights, you need to be sure that your reports are giving you the right data.

We’ve seen businesses who didn’t realise there were errors on their reports until months after their system was set up – which meant the costs of those errors kept growing under the surface – and let’s not even get started on the potential for errors on your tax returns!

So, what’s next?

If you’ve set up your own inventory management system recently, it’s time to take a good look at your reports – the earlier you find a problem, the better! If you’re still unable to pinpoint why your systems aren’t working for you – we can help.

Take a look at some of the clients we’ve worked with over the years who we’ve helped transform their processes and systems for improved efficiency and better visibility of their sales and overall data. Or, if you’re ready to finally see the true potential of your system, get in touch to see how we can help.